FACTORY

AUTOMATION

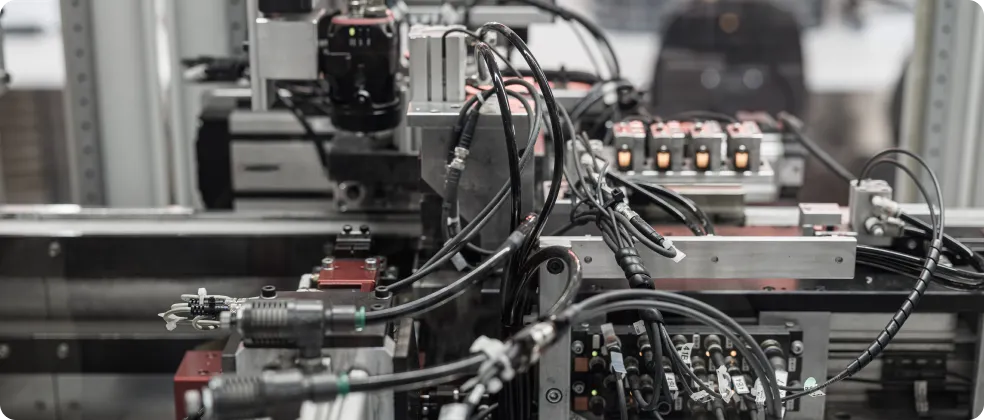

Wiring-related Issues in FA

Issue 1

Heavy Wiring Workload

Cables must be installed for every sensor, creating significant labor during initial setup

and layout changes.

Ongoing cable inspection and maintenance are also required to prevent downtime.

Issue 2

Sensor Placement Constraints

Wiring limits sensor installation in areas with complex motion, such as robotic joints and rotary tables, restricting flexible layouts.

Issue 3

Downtime Caused by Cable Failure

Cables wear and degrade, especially around moving robot parts. A single cable failure can stop the entire line and disrupt production plans.

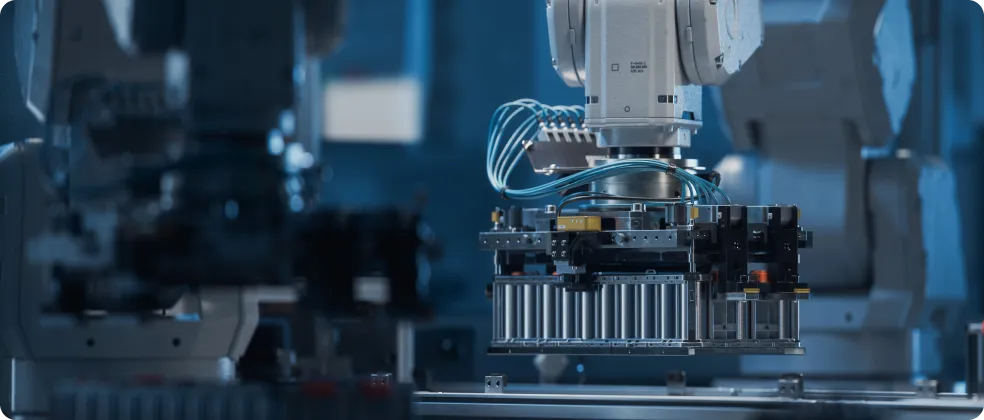

Eliminating the Burden of Wiring

By making sensors wireless, we significantly reduce installation effort and eliminate the risk of

downtime caused by cable failures.

Wiring-related maintenance and adjustments are no longer required, reducing maintenance

time.

Sensor placement constraints in complex moving and rotating parts are also eliminated, enabling

more flexible process design.

Joint Development Case

"In collaboration with SMC Corporation, a global leader in pneumatic control equipment, we developed a fully wireless auto switch. Powered wirelessly by our proprietary AirPlug technology, it operates without cables or batteries, eliminating the risk of failures caused by cable breakage."

WPT Evaluation Kit

A modular platform designed to accelerate PoC and prototyping using 920 MHz RF wireless power

transfer.

The kit includes both a transmitter and a receiver, enabling immediate wireless powering and

operation of sensors and IoT devices.

All RF and power management circuits are pre-optimized, eliminating the need for complex

impedance matching or power design.

Simply connect your application circuit to get started.

Contact Us